![]() 上海彌牡智能科技有限公司

上海彌牡智能科技有限公司

As a linear bearings manufacturer, NB is serving a variety of customers in many industries such as general machinery, semiconductor equipment, special purpose machines.

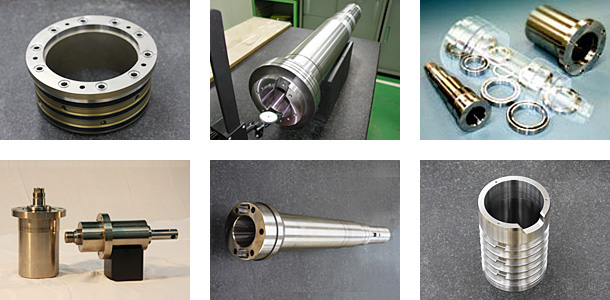

The NB SPINDLE is a further contribution to the industry. From parts to the spindle unit NB conducts integrated production through total manufacturing.

Please contact us for any requirement.

NB keeps supplying high quality products through skilled labor with time-nurtured skills, time-tested production process and technology, in addition to a help of the state-of-the art technology and equipment.

NB keeps supplying high quality products through skilled labor with time-nurtured skills, time-tested production process and technology, in addition to a help of the state-of-the art technology and equipment.

We have a belief that high processing technology is the key to customer-satisfaction.

| Outer Surface Machining | Range |

| Maximum diameter | 650mm |

| Maximum length | 6000mm |

| Surface roughness | Ra0.4 |

| Straightness | customer specification |

| Concentricity | customer specification |

| Perpendicularity | customer specification |

| Cylindricity | customer specification |

| Internal Surface Grinding | straight or tapered internal portion |

| Deep Hole Machining | ||

| Hole diameter | Maximum length | |

| one side | through hole | |

| Φ2~2.5mm | 200 | 400 |

| Φ3~3.5mm | 300 | 600 |

| Φ4~8mm | 500 | 1000 |

| Φ9~10mm | 750 | 1500 |

| Φ10~32mm | 850 | 1700 |

| Φ30~80mm | 2000 | 4000 |

| Screw Grinding | triangular and trapezoidal screws |

| Matched parts | special nuts to match a given shaft, tapered portion of inner or outer diameter to match a given shaft or bearing |

| General machining | center tapping, step machining, V-groove machining, screw machining, plate-groove machining, key-groove machining, flat surface machining, spot hardening |

| Surface Treatment | industrial chrome plating, low temperature black chrome treatment, other customer request |

| Thermal-spraying Ceramic-coating (best-suitable for parts that require wear and corrosion resistance) | |

|

(1) standard material high carbon chromium bearing steel (SUJ2) chrome molybdenum steel (SCM415, 435) carbon steel for machinery (S45C) martensite stainless steel (equivalent to SUS440C ) austenite stainless steel (SUS303, 304) steel alloy for tools (SKS3, SK4) aluminum chrome molybdenum steel (SACM645) |

(2) standard ceramic for thermal-spraying main component: TiO2 titanium dioxide specific gravity: 4.7 hardness: 58HRC or more maximum temperature: 540℃ color: black fine surface finish by grinding |